Profile:

Profile:

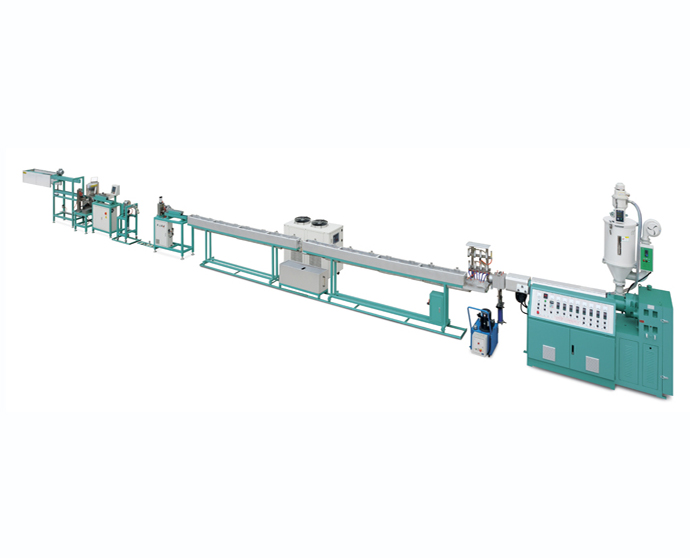

The electrical control system of this production line is controlled by OMRON PLC and touch panel. Equipped with intelligent algorithm, it sets the parameter through touch panel to realize the punching, automatic 45°corner cutting at both ends, automatic feeding by mechanical arm while producing door seal. The entire production line only needs one staff to reach the qualified product, with easy operation, precise size and high production efficiency.

Technical process:

Technical process:

PVC aggregate, secondary crushing aggregate→mixing and drying→heating, extruding, molding→cooling, shaping→traction→automatic punching→automatic 45°corner cutting at both ends→automatic feeding→taking away the finished door seal manually.

Elements of production line:

Elements of production line:

1. Automatic drying and feeding machine

3. Automatic hydraulic screen exchanger

7. Automatic punching, cuntting and pick-up unit

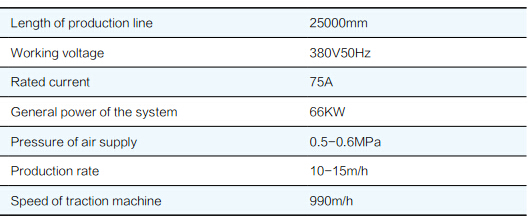

Technical parameter:

Technical parameter: